Best Textured Polycarbonate Sheet

Best Textured Polycarbonate Sheet You Could Find In China

Textured Polycarbonate Sheet Introduction

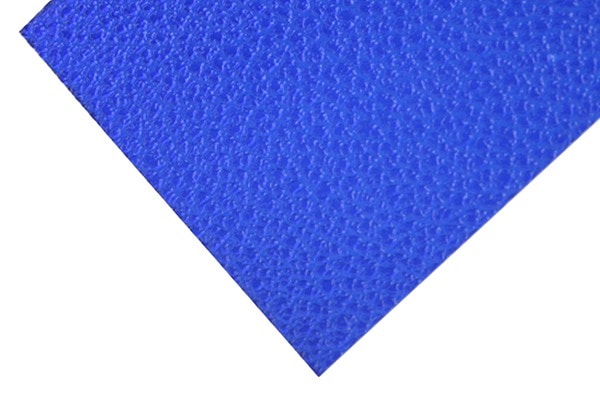

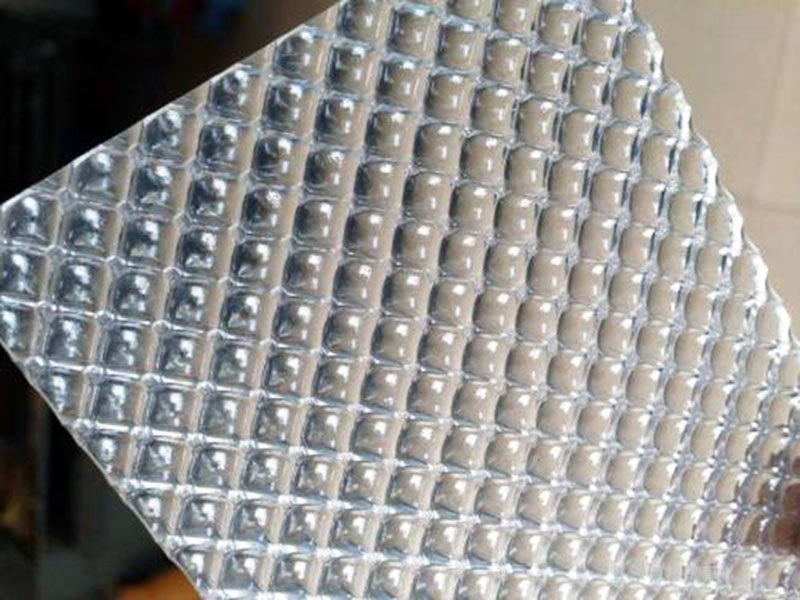

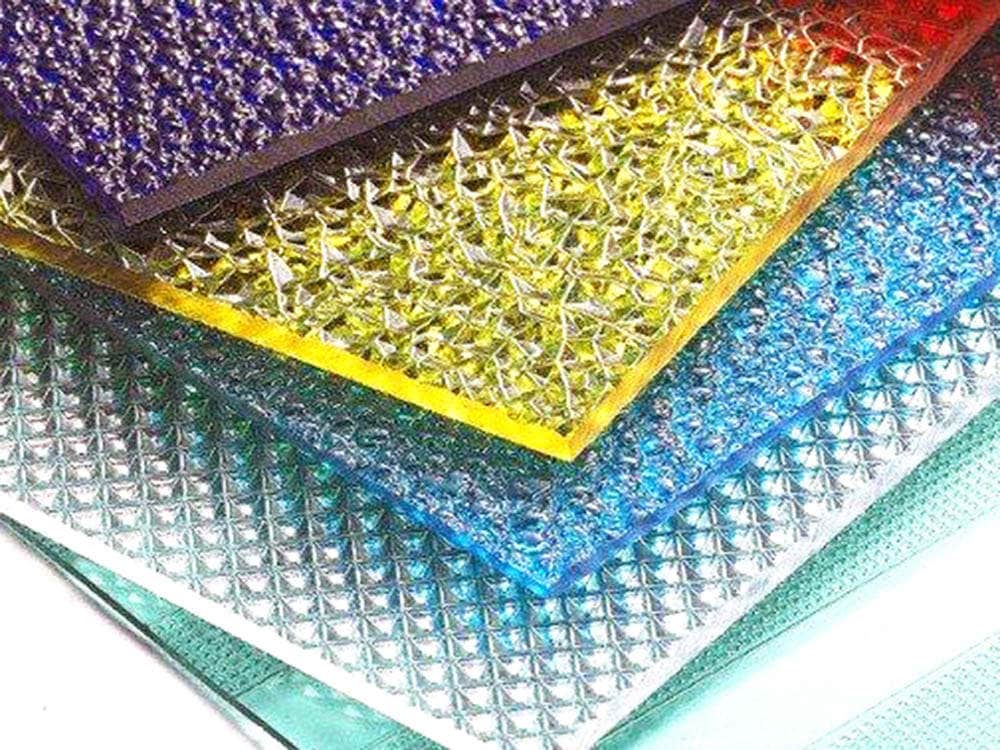

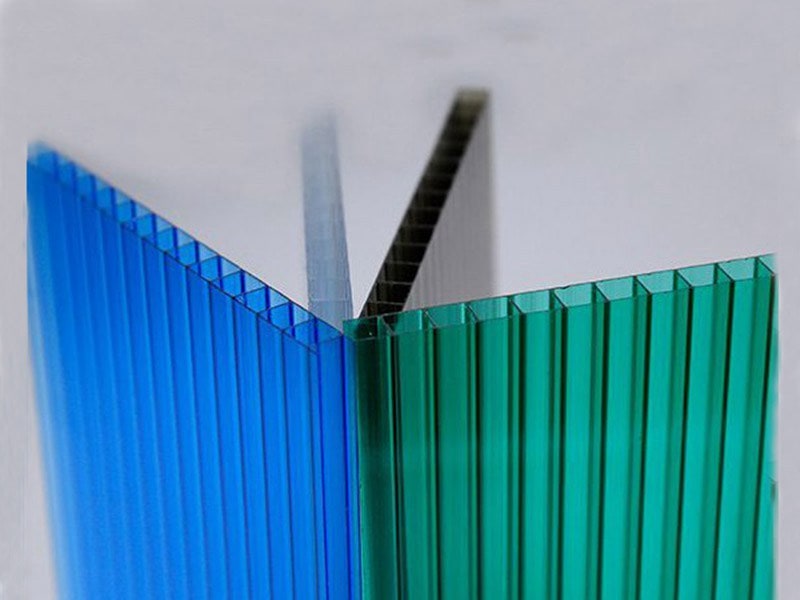

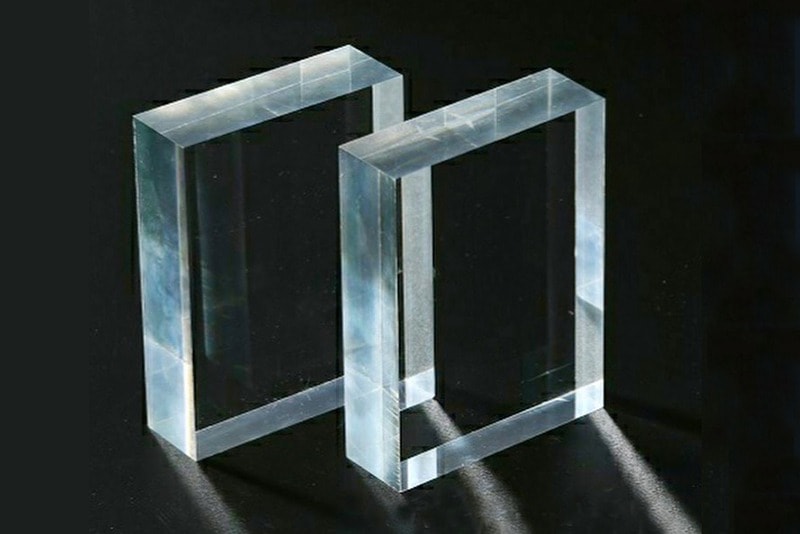

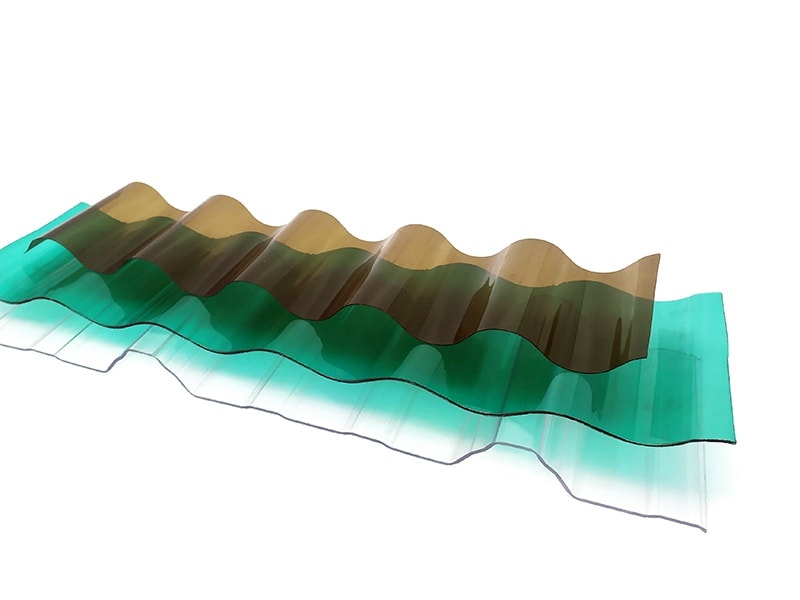

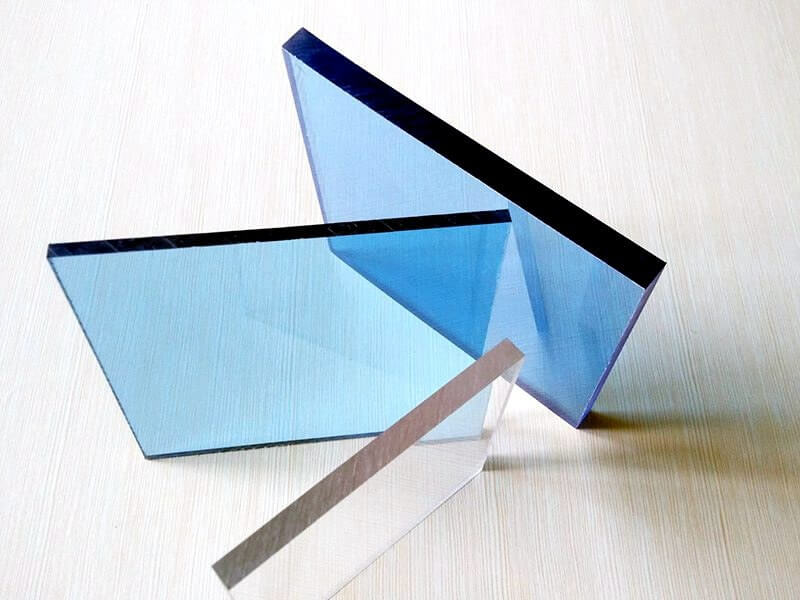

Textured Polycarbonate Sheet is designed with a special pattern on one side and smooth on another side. Some people call it “Prismatic Polycarbonate Sheet”, “Embossed Polycarbonate Sheet”, and “Polycarbonate Texture”. It is an excellent solution to applications where you require blurred vision and reduce glare light rays. As the most popular plastic sheets, the embossed polycarbonate sheet is used widely for industrial glazing, lamps, and lanterns, privacy screens, shower screens, decorative panels, etc.

With more than 15 years of experience in the polycarbonate field, UVPLASTIC offers three types of surface textures including diamond pattern, prism pattern, orange peel pattern. Otherwise, we provide the global client with the integrated machining services, including cut to size, coating layers, thermal forming service.

Textured Polycarbonate Sheet Specification

Standard Size

| Model | Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|---|

| UVFPC-EM | 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 15mm | 1220mm, 2100mm, Custom Width | 2400mm, 5800mm, Custom Length |

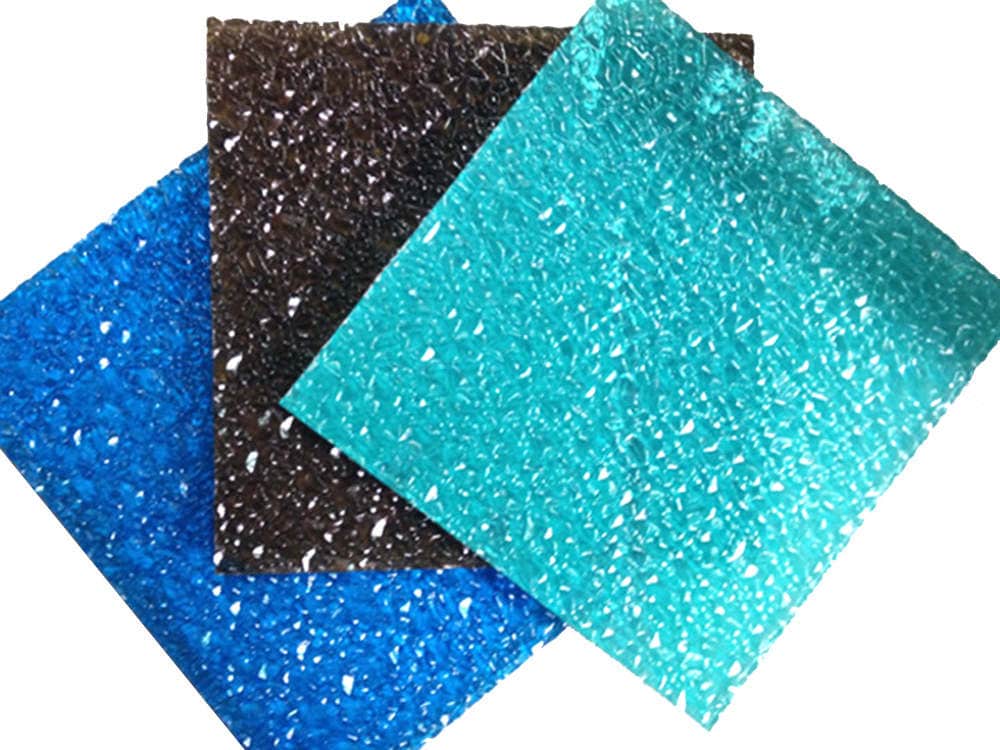

Color Options

| Type | Colors Description |

|---|---|

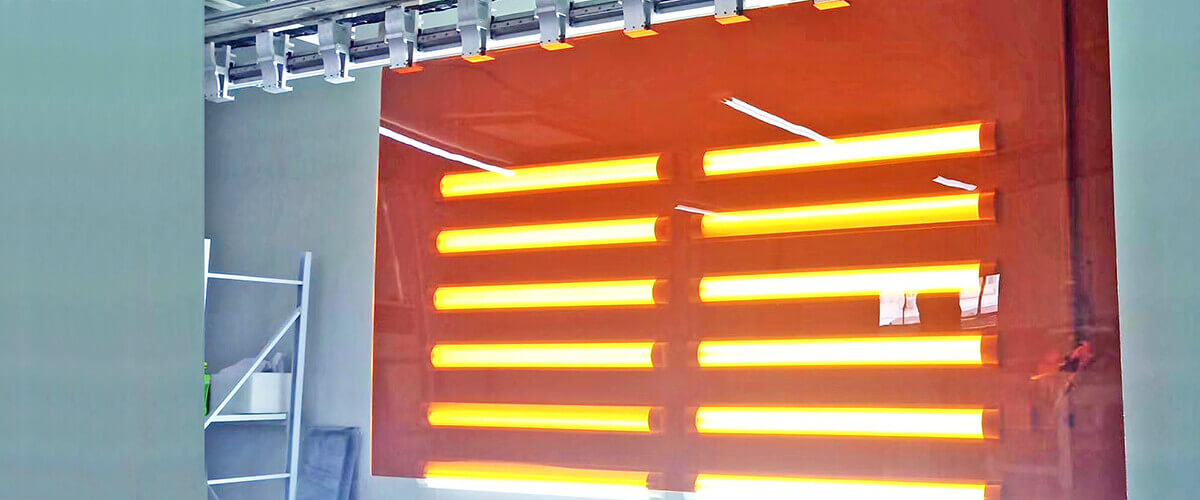

| Transparent | Clear, Brown, Bronze, Gary, Red, Blue, Lighter Blue, Green, Lighter Green |

| Translucent | Black, White Opal, White Diffuser, Yellow, Red, Mint Green, White Opal |

| Opaque | Black, White Opal, Yellow, Dark Blue, Red, Dark Grey, Dark Brown |

The standard color is transparent. But custom colors are available subject to MOQ.

Clear Texture Polycarbonate Yellow Texture Polycarbonate Blue Texture Polycarbonate Green Texture Polycarbonate

Physical Properties

| Physical Properties | Testing Method | Value | Unit |

|---|---|---|---|

| Specific Gravity | D-792 | 1.2 | g/cm3 |

| Tensile Strength at Yield | D-638 | >60 | Mpa or N/mm² |

| Tensile Strength at Break | D-638 | >65 | MPa or N/mm² |

| Coefficient of Linear Thermal Expansion | D-696 | 0.065 | mm/m °C |

| Thermal Conductivity | C-177 | 0.21 | W/m K |

| Elongation at Break | D-638 | >100 | % |

| Tensile Modulus of Elasticity | D-638 | 2400 | MPa |

| Flexural Strength | D-790 | 100 | MPa |

| Fire rating | UL 94 | V2 | / |

UV Protective Layer

| Model | Description |

|---|---|

| UVFPC-EM | Texture surface is on one side, stabilized UV protective layer for general purpose |

| UVFPC-EM-U1 | Texture surface is on one side, co-extruded UV protective layer on one side for outdoor application |

| UVFPC-EM-U2 | Texture surface is on one side, co-extruded UV protective layer on both sides for outdoor application |